Hello at the halfway point of our 10 high-performance principles!

Welcome to the sixth issue of Bottle Bill Common Ground — a limited-series newsletter from Reloop North America highlighting evidence-based guidance for legislators, policy makers, industry, and advocates working on bottle bills. (If you haven’t read our first four issues, you can do so here.) This issue focuses on Principle #6 of the 10 high-performance principles for an effective deposit return system (DRS). A key stop on a beverage container’s journey through a DRS is the retailer or redemption center that collects it from the consumer, then handles, sorts, and stores the redeemed container before it gets picked up for recycling.

A key stop on a beverage container’s journey through a DRS is the retailer or redemption center that collects it from the consumer, then handles, sorts, and stores the redeemed container before it gets picked up for recycling.

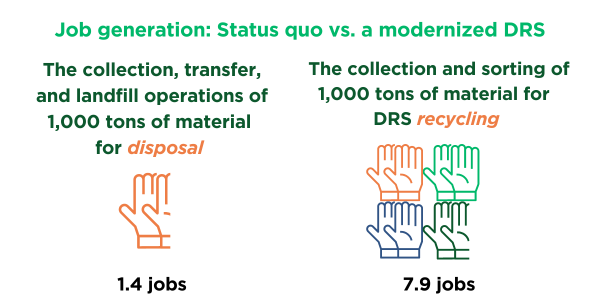

We know from all available research in the US and Europe that collecting and sorting containers in a modernized DRS creates new jobs.

Reloop North America did targeted research on the impacts of DRS modernization n five Northeast states (CT, ME, MA, NY, VT) and found, among others, this economic impact:

While this is good news, the point is not just about the quantity of jobs, it’s also about the quality of pay for workers at the return points. The work of collecting, sorting, and storing those beverage containers does not, and should not, come free. The businesses providing the service rightfully receive a “handling fee” calculated to offset the costs incurred in hosting and operating a return point. And that handling fee needs to be fair.

Handling fees are best set to allow for flexibility based on the cost of the actual service provided. Setting them in legislation only politicizes the process and subjects legislators to lobbying from retailers eager for a fee increase and from producers generally opposed to any change that increases their costs.

Who sets the handling fees? That depends on whether the DRS is centralized or decentralized. In a centralized system — used in all of Canada, most of Europe, and a few states (Oregon, California, Hawaii) — then the system operator determines the fee. In a decentralized system, it may be done by the regulating authority. (Details coming up soon in Principle 8: Clear System Standards & Functions as well as when we move into our 10 Essential Practices to build into bottle bill legislation and running a DRS.)

Who pays the handling fees? Always the system operator, which usually means the producers. In California, however, it’s an entity named CalRecyle. In Hawaii, it’s the Department of Health.

Questions to consider when setting the right and fair handling fee need to take into account the realities of return points, including:

- Is the return point a retailer or a stand-alone redemption center?

- How are the beverage containers recovered? Are they handled manually by workers or automatically via reverse vending machines (RVMs)?

- What is the condition of the containers they handle? Are they compacted or uncompacted?

- What is the container material? What are the different handling costs for each type of material (e.g. aluminum, PET plastic, glass)?

- Is a commingling agreement in place (where containers are sorted by type and size rather than by brand)?

- What are the local costs of space, labor, equipment purchase and maintenance, site setup and maintenance, and utilities?

Reviewing handling fees at set periods, either annually or biannually, by the system operator or the state agency, in consultation with return point operators, helps guarantee they remain responsive to changing conditions.

Modernizing a DRS with fair handling fees pays dividends in multiple ways. The existing and newly created jobs are filled by workers who are paid fairly, resulting in greater retention and less recruitment and training. Installing technology at redemption points allows the counting of containers using their barcodes. Barcode counting not only helps mitigate fraud but can also be used to accurately determine fair handling fees to return locations. Stay tuned for Principle #9: Producer Reporting on Units Sold to learn more about this and how all 10 Principles work together for a high-performing deposit return system that returns economic and environmental benefits for all.

Thanks for reading! We encourage you to share this newsletter widely with those who want or need to know about these principles and practices. Working together from a common ground of knowledge, we can move good bottle bills forward. Sign up here to get these blog posts as emails.